Prototyping

In todayís fast moving business climate itís evermore important to be able to communicate quickly and accurately between customers and suppliers.† Hemings Engineering has addressed this need with the implementation of the Radan suite of CAD/CAM software for 3D Modelling.

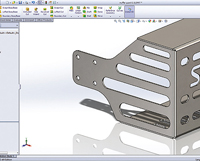

3D software models of complex sheet metal fabrications and full assemblies can be generated to eliminate design errors before any sheet metal work is undertaken.† 3D and 2D images can then be used to help visualise your own designs for manufacturing suitability.† Where you only have a sample we can produce 2D drawings to work to in manufacturing and for your future reference.† These drawings can be output in AutoCAD compatible file formats DWG and DXF.† We can also import your 3D data in the form of SAT format to speed up CNC program generation.† 2D developments can be automatically and accurately produced ready for CNC tooling and nesting.

The use of Radanís automatic sheet nesting capabilities enables us to quickly try out different CNC punching nests to evaluate the best material utilisation.† Radan CAD/CAM software helps us to drive down cost, which in turn is passed on to you

Laser Profiling

We have an Amada Alpha LC1212 2KW Laser.

10mm mild steelcapacity.

3mm Stainless Steel capacity.

2500 x 1250mm sheet capacity.

Punching

We have a CNC punch with a wide range of tooling available to help keep costs to a minimum.

Automatic tool change for speed of work.

3MM mild steel capacity

2.5m x 1.25m sheet capacity

Forming

Much of our regular work is the forming of both simple and complex brackets and electrical enclosures.† We can work with a range of material including mild steel, aluminium and stainless steel.

We have a Safan E Brake press brake that currently leads the way in folding technology.

30% faster than traditional hydraulic press brakes.

50% less electricity used enabling us to stay competitive in our pricing.

We also have an Amada HFE MK2 80/25 7 Axis Press Brake for large complex components.

Welding and fabrication

We are fully equipped with both Mig and Tig welding facilities.

We can work with aluminium, stainless steel and mild steel.

We can undertake small to large batch fabrication.

Machinery

Amada HFE MK2 80/25 7 Axis Press Brake

Safan E Brake Electro Syncro high-speed press brake

LVD Delta 1250 Turret Punch††††††††††††††††††††††††

Radan 3D design Cad/Cam system

Mig/Tig welding

CNC Tap Drill Centre

Auto band saw

Piller drills

Pemserter Insert Press